Precision building framework drafting is key to effective steel framing, ensuring structural integrity and fabrication accuracy through skilled use of standard steel sizes, connection types, and computer-aided design (CAD) software. Meticulous planning, detailed documentation, and advanced automation techniques mitigate errors, enhance project quality, and ultimately bolster the safety and durability of buildings.

In the realm of construction, steel framing has emerged as a game-changer, revolutionizing building framework drafting. For precise and efficient structures, understanding the fundamentals of steel framing and its connection detailing is paramount. This article explores critical aspects such as basic framing concepts, the significance of connections, detailed design considerations, and fabrication techniques to ensure accuracy in every step. By delving into these elements, builders can create robust and durable frameworks.

Understanding Steel Framing Basics for Accurate Drafting

Understanding steel framing basics is paramount for achieving precise drafting in building framework design. Steel framing, a key component in modern construction, relies on accurate measurements and detailed connections to ensure structural integrity and performance. Architects and engineers must familiarize themselves with standard steel sizes, dimensions, and grades to create reliable digital blueprints. Knowing the properties of different steels allows designers to select appropriate materials for specific project needs.

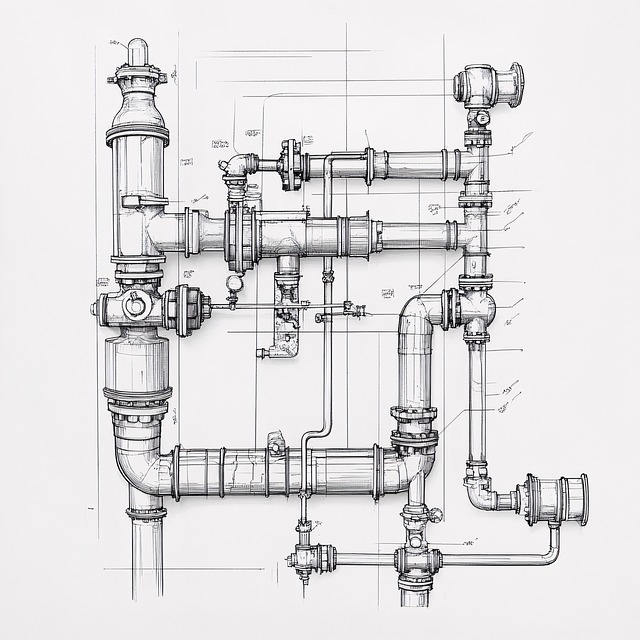

Accurate drafting involves not only meticulous attention to dimensional details but also a deep understanding of connection types and detailing. Properly detailing steel connections is crucial to withstand loads and forces during fabrication and assembly. Standardized connection methods, like bolt patterns and weld specifications, play a vital role in ensuring structural efficiency and consistency throughout the building framework.

Key Components: Connections and Their Importance

In the realm of steel framing, connections play a pivotal role in ensuring fabrication accuracy and structural integrity. These key components include various types of joints, bolts, and fasteners that hold together the building framework. Each connection point is critical as it dictates the overall stability and performance of the structure. Accurate drafting of these connections during the initial design phase is paramount; even minor discrepancies can lead to significant errors in fabrication and assembly.

Properly designed connections facilitate seamless integration of steel members, allowing for efficient fabrication and precise alignment on site. They also help distribute loads effectively, ensuring the building framework can withstand various structural stresses. By prioritizing detailed connection drafting, engineers and architects can enhance overall project quality, reduce potential delays, and foster a robust and reliable construction process.

Detailed Design: Creating Robust Connection Details

In the realm of steel framing, precise connection detailing is paramount for fabrication accuracy and structural integrity. Detailed design plays a crucial role in ensuring that every joint and fastening point meets the required strength and stability standards. Skilful building framework drafting involves creating intricate connection details that account for various load types, environmental factors, and material properties.

By meticulously documenting these connections, fabricators can ensure consistency during construction. This process includes selecting appropriate fastening methods, defining bolt load ratings, and specifying spacing requirements. Such meticulous design considerations ultimately contribute to the overall durability and safety of buildings, making detailed connection detailing a vital aspect in the world of steel framing.

Fabrication Techniques to Ensure Precision in Steel Framing

In the realm of steel framing, fabrication precision is paramount for structural integrity and overall project quality. Advanced techniques in building framework drafting have significantly enhanced this process. Professionals employ detailed computer-aided design (CAD) software to create accurate 2D and 3D models, minimizing errors often introduced during manual drafting. This digital approach allows for meticulous planning of each component, from beam dimensions to connection points.

Furthermore, automation in fabrication processes ensures consistency and reduces human error. Laser cutting, for instance, offers unparalleled accuracy when creating steel panels and frames. Automated welding robots can precisely join components, maintaining the integrity of the building framework’s design. These techniques are pivotal in achieving seamless connections, ensuring the final structure meets strict safety standards and performs optimally throughout its lifespan.

Precision in steel framing is paramount for structural integrity and project success. By understanding the fundamentals of steel framing, recognizing the significance of connections, and employing detailed design practices along with suitable fabrication techniques, architects and engineers can ensure accurate building framework drafting. These measures lead to robust structures that meet safety standards and enhance overall construction quality.