Structural drafting services play a pivotal role in bringing innovative steel truss and beam designs to life. By translating complex engineering concepts into meticulous CAD drawings, these services ensure precise material specifications, optimal construction, and enhanced structural integrity. Advanced stress analysis predicts failure points, enabling strategic reinforcement for safety. Custom detailing optimizes load distribution, improves strength-to-weight ratios, reduces costs, and yields lightweight, aesthetically pleasing structures. Skilled drafters provide detailed technical drawings, facilitating efficient project management, cost optimization, and the longevity of buildings through robust steel trusses and beams.

In the realm of structural engineering, custom steel truss and beam detailing plays a pivotal role in load distribution, enhancing both structural integrity and efficiency. This article delves into the intricacies of steel truss design basics, exploring critical aspects such as beam loading and stress analysis. We uncover custom detailing techniques that optimize load bearing capabilities, while emphasizing the paramount importance of structural drafting services in ensuring safety and streamlining construction processes.

Understanding Steel Truss Design Basics

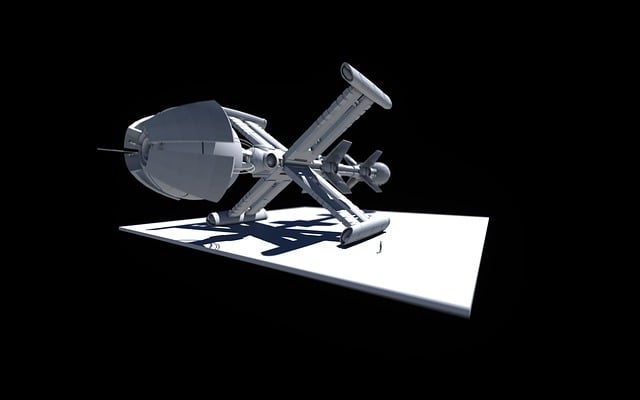

Steel trusses have revolutionized structural engineering, offering a lightweight yet incredibly strong solution for spanning wide areas. At the heart of this design lies a meticulous understanding of load distribution and efficient material utilization. The basic truss structure comprises interconnected triangles, which ensure stability through tension and compression forces. This simple yet elegant design is a cornerstone of many architectural marvels, from bridges to modern skyscrapers.

Professional structural drafting services play a vital role in transforming these designs into tangible structures. Draftspers possess the expertise to interpret complex engineering concepts and translate them into detailed drawings, ensuring accurate material specifications and precise construction. By leveraging computer-aided design (CAD) software, they can create intricate truss patterns, consider various loading scenarios, and optimize the layout for optimal structural integrity and efficiency.

Beam Loading and Stress Analysis

Beam loading and stress analysis are critical components in designing custom steel truss and beam systems, ensuring optimal load distribution for any structure. Understanding the various loads a beam will encounter—such as dead weight, live loads, and environmental factors like wind or seismic activity—is essential for determining the appropriate material properties and section dimensions. Structural drafting services employ advanced computational methods to predict stress concentrations and potential failure points, allowing engineers to make informed design decisions.

Through meticulous analysis, professionals can identify critical areas of a beam’s structure, incorporating strategic detailing and reinforcement to manage and distribute loads efficiently. This process not only enhances the structural integrity but also guarantees that the final product meets safety standards while optimizing material usage, resulting in cost-effective and reliable steel truss and beam solutions.

Custom Detailing Techniques for Optimal Distribution

Custom detailing plays a pivotal role in optimizing load distribution within steel truss and beam systems. Skilled engineers utilize advanced structural drafting services to create intricate designs tailored to specific project requirements. By meticulously considering factors like span, load types, and material properties, they develop innovative solutions that ensure uniform stress levels and enhance overall structural integrity.

These custom detailing techniques involve strategic placement of connectors, reinforcement members, and adjustment brackets. Such precision engineering not only improves the strength-to-weight ratio but also enables efficient use of materials, reducing waste and project costs. The result is a robust, lightweight, and aesthetically pleasing structure, meeting both functional and aesthetic objectives.

Structural Drafting Services: Ensuring Safety and Efficiency

Structural drafting services play a pivotal role in ensuring the safety and efficiency of custom steel truss and beam systems. Skilled drafters specialize in creating precise technical drawings that accurately represent structural designs, incorporating load distribution calculations and material specifications. These detailed blueprints serve as the blueprint for fabrication and installation, guaranteeing that each component is tailored to withstand specific loads and environmental factors.

By leveraging structural drafting services, engineers and architects can confidently visualize and communicate complex structural concepts. This level of detail enables efficient project management, cost optimization, and minimal rework during construction. Ultimately, it contributes to creating durable, structurally sound trusses and beams that enhance the overall integrity and longevity of buildings and structures.

In conclusion, custom steel truss and beam detailing play a pivotal role in load distribution, ensuring structural integrity and efficiency. By understanding basic design principles, performing detailed loading analyses, and employing advanced custom detailing techniques, engineers can optimize material usage and create robust structures. Structural drafting services are essential in this process, providing precise blueprints that guarantee safety and streamline construction processes, making them indispensable for any architectural endeavor involving complex steel trusses and beams.